We are the Distributor of Honeywell | City Technology Oxygen (O2) Sensors

4OXV CiTiceL®

Oxygen (O2

) Gas Sensor

Part Number: AAY80-390

Buy 4OXV O2 Sensor NoW

4OXV consists of

more than 20 individual components, which are manufactured

to exceedingly tight tolerances and assembled to create the

finished product on an automated assembly line.

Each component performs a specific purpose to ensure the

product’s performance throughout its anticipated two-year life.

Key Features and Benefits:

- False alarm immunity

- Enhanced response time in extreme applications

- Reliably meets stated life

- Superior environmental performance

Download

4 Series 4OXV CiticeL Oxygen (O2) Gas Sensor Product Data Sheet

Technical Specifications

Measurement

- Technology : Electrochemical

- Measurement Range : 1-25% vol. O2

- Maximum Overload : 30% vol. O2

- Output Signal* : 0.10 ± 0.02 mA in Air

- Response Time (T90)* : <15 Seconds

- Zero Current (Offset)* : <0.6% vol. O2

- Linearity : Can be considered linear in many cases.

See Operating Principles (OP-02) for further details.

Electrical

- Recommended Load Resistor : 100 Ω

Mechanical

- Casing Material : ABS

- Weight : <16 g

- Orientation Sensitivity : <0.2% vol. O2 equivalent

Environmental

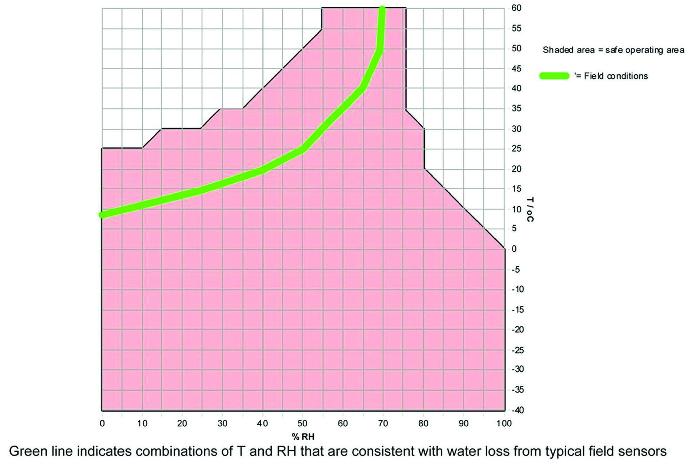

- Operating Temperature Range : -20°C to +50°C (up to 3 months continuous across RH range)

- Recommended Storage Temp : 0°C to 20°C

- Thermal Transient : <23.5% vol. O2

(Temp. plunge +22°C to -20°C) - Operating Pressure Range : Atmospheric ± 20%

- Pressure Coefficient : <0.02% signal/mbar

- Pressure Transient : <200% signal change

(60 cm H2O step change) - Relative Humidity Range : (at 0°C to 20°C) When installing the sensor into instrumentation,

Continuous : 5 to 95%RH non-condensing

Short Term : 0 to 99%RH non-condensing

Lifetime

- Long Term

Output Drift* : <2%

signal/month

Typically <5% over operating life - Expected Operating Life : Minimum 24 months in air

- Storage Life : 6 months in original packaging

IMPORTANT NOTES All tolerances ±0.15 mm unless otherwise stated. Do not remove label. Do not solder to pins. When installing the sensor into instrumentation, the sensor vent hole should not be blocked. The instrument should also be adequately vented. If the sensor vent hole is blocked or if the instrument is not adequately vented, sensor performance will be compromised. For further details, refer to Operating Principles OP02.

* Specifications are valid at 20°C, 50% RH and 1013 mBar, using City Technology recommended circuitry. Performance characteristics outline the performance of sensors supplied within the first 3 months. Output signal can drift below the lower limit over time.

Reliability

The 4OXV has improved pin retention and O-ring sealing to

prevent electrolyte leakage. It also has enhanced sealing

between the internal membrane upon which the catalyst is

mounted and the liquid electrolyte, preventing seepage into the

internal plenum chamber and possible blockage of the input

capillary. Internal electrolyte leakage will potentially cause the

instrument to fail because air cannot enter through the capillary.

External leakage where electrolyte seeps though the seals

between the pins and the unit’s body can, apart from the

obvious failure of the sensor itself, result in irreparable damage

to the instrument’s PCB.

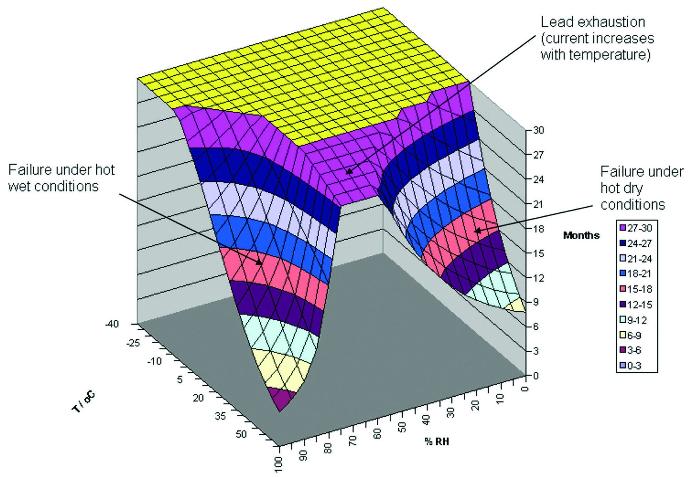

Lead exhaustion

By the nature of the electrochemical reaction upon which

the sensor’s operation is based, the lead anode is oxidised

over time. The anode assembly in 4OXV has a fused base,

guaranteeing connectivity with all the lead strands from which

it is made and the current collector is deeply embedded in the

structure, ensuring good connectivity with the output pin.

The anode’s design ensures that lead exhaustion will not occur

prematurely before the end of the sensor’s 24-month design life.

Conclusions

The introduction of the new 4OXV is the latest development in

the evolution of the capillary oxygen sensor for use in life safety

equipment. A major improvement in stability when the unit is

subjected to rapid temperature or humidity changes

significantly improves the operational reliability of the sensor,

giving instrument manufacturers the confidence that false

readings will not be generated when the unit is subjected to

rapid environmental changes.

Improved reliability through enhanced sealing reduces

premature failures and consequently builds user confidence in

the detector.

Our Best-Selling Sensors

We are also the only licensed distributor of ACD Calibration Gas Generators in the UK.

If you need help?

Don't hesitate to email us sales@spantech.co.uk if you need assistance.