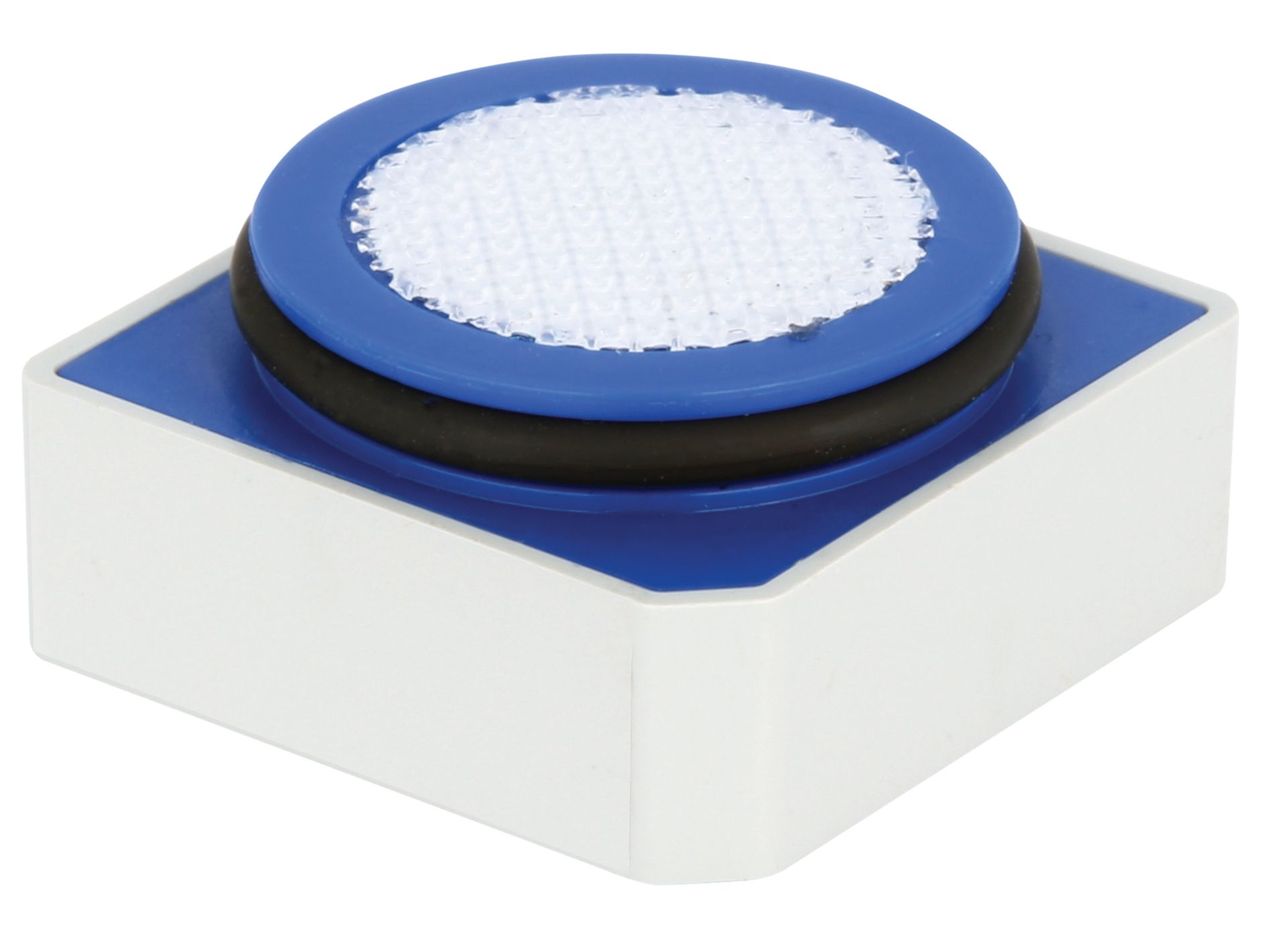

Honeywell City Tech iSeries Next-Generation Intelligent Series

Digital Gas Sensors

These sensors have a digital interface, longer life and numerous built-in diagnostics features.

The iseries’ intelligent diagnostic features

help enhance the overall instrument

performance, making them smarter and

safer by indicating faults and monitoring

health, thereby decreasing downtime and

cost of ownership.

The ease of integration combined with

pre-calibration drives a significant benefit

to OEMs and users in terms of integrating

the sensors easily into the instrument.

Inbuilt OEM lock code can be used to prevent

unauthorized third-party replacement

of sensors in the field.

With an extended

operating life of five years and extended

temperature and humidity range, iseries

sensors are apt for usage in wide range of

applications and climatic conditions.

Available now:

- Electrochemical: CO, H2S, SO2 & O2

- Pellistor: LEL

|

|

|

|

The iseries platform uses internal tests to monitor the condition of the sensor and apply algorithms both to compensate for drift and to predict when the sensor accuracy exceeds a predefined limit and needs recalibrating. It can also predict when it is wearing out and can give warning in advance that the sensor needs replacing. As both the Predictive Calibration and End-of-life indication use predictions based on the environment that the sensor is being used.

Definition of Diagnostic Tests Predictive Calibration: The calibration process can be very tedious, costly and a time-consuming process. With this function, sensors can predict in advance when its accuracy is becoming too poor to give a reliable reading. This function helps to identify exactly when a recalibration is required. The sensor can estimate the time to recalibration up to six months in advance. Recalibration intervals will be typically at least twice as long as for conventional sensors and will adapt depending on the environment – with sensors used in more benign environments needing less frequent calibrations than those in aggressive ones.

The user can configure the accuracy limit of the sensor, and this will determine the interval at which the calibration is needed. In other words, the tighter the accuracy value, the more frequent calibration needed. The user can therefore trade off accuracy against recalibration interval. There is also a configurable built in fixed interval recalibration countdown timer for applications where legislation requires calibration at certain intervals.

End-of-Life: The lifespan of a sensor depends mostly on the environmental conditions at which the sensor is exposed. With this function, the sensor can predict in advance when its sensitivity is falling too low to give a reliable and accurate reading. When the End-of-life function is triggered, the sensor automatically warns the instrument via a set of fault flags sent together with the gas reading. If the fault is detected the instrument can warn the user to stop using the sensor.

How accurate are the End-of-life and Predictive Calibration functions? The predictive model for End-of-life and time to calibration is highly accurate if the environmental conditions remain adequately constant. An analogy to this is the ETA (estimated time to arrival) in a car’s GPS system, which is based on previous average speed. If you travel at a constant speed, the ETA will count down linearly and be quite accurate over long distances. However, if you speed up or slow down the ETA could increase of decrease significantly throughout the journey. Similarly, if a sensor is kept in constant conditions, the future prediction based on historical conditions should predict a long way into the future quite accurately, and as a result the time to end of life or recalibration would decrease linearly over time. If the sensor is put into a more aggressive environment, then its predicted time to EOL/ recalibration will start to drop rapidly, whereas if a sensor that has been running in aggressive (e.g. dry) conditions is transferred to more benign conditions, the time to end of life or recalibration prediction may even increase over time .

Need help?

Don't hesitate to email us sales@spantech.co.uk if you need assistance.