Which gases we can use for bump testing?

The choice of gases for bump testing depends on the specific type of gas detectors or monitors being used and the gases they are designed to detect. Here are some common gases used for bump testing based on the types of detectors:

- Single Gas Detectors:

- Hydrogen Sulfide (H2S): Common in industries like oil and gas, mining, and wastewater treatment.

- Carbon Monoxide (CO): Found in various industrial settings and confined spaces.

- Oxygen (O2): Important for ensuring safe oxygen levels in confined spaces.

- Multi-Gas Detectors:

- Multi-gas detectors can detect a combination of the gases mentioned above along with others like:

- Combustible Gases (LEL/LEL%): Such as methane (CH4), propane, butane, and other flammable hydrocarbons.

- Specific Gases:

- Depending on the industry, specific gases might be relevant. For instance:

- Ammonia (NH3): Used in industries like agriculture, refrigeration, and chemical manufacturing.

- Chlorine (Cl2): Used in water treatment and chemical industries.

- Sulfur Dioxide (SO2): Common in industries involving combustion processes and chemical production.

- Volatile Organic Compounds (VOCs):

- These are gases emitted from certain solids or liquids and can be harmful in high concentrations. Some portable detectors can be calibrated to detect specific VOCs.

It's important to refer to the manufacturer's guidelines and specifications for your specific gas detection equipment to determine the appropriate gases for bump testing. Using the correct reference gases ensures that the detectors are accurately calibrated and providing reliable readings. Bump testing is a safety measure to ensure that the detectors are functioning correctly before entering hazardous environments.

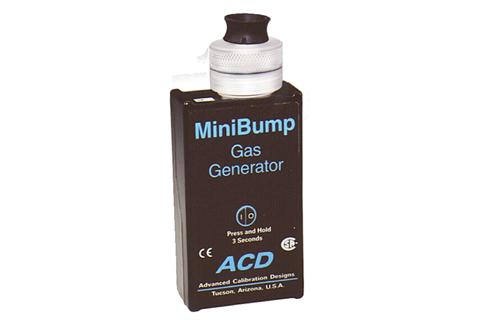

Simply put, Advanced Calibration Designs calibrators are gas generation devices that are superior to the previous approaches to gas sensor calibration equipment for the health and safety industries.

Advanced Calibration Designs exceed the limitations of all previous forms of calibrating gas monitors. They do this through Integrated and Expandable products that provide the backbone of the new era in calibration gas standards.

ACD products generate the gas on demand rather than storing it, providing many advantages over the old approaches. Since there is no gas present until the user requests it, and the gas is never under pressure. ACD products are safe for air transport and do not deteriorate over time. It is not uncommon for customers to use the same calibration source for 5, 10 or even 15 years of calibration.

The on-demand generation of the gas allows a single calibration source to generate adjustable concentrations. Cylinders are a single fixed concentration. Most ACD generating sources can provide concentrations of between 0.25 and 125 parts per million. In addition to this, the flow rate can be varied between 0.2 and 1.0 liters per minute using the internal pump. Calibrations of sample drawing gas detectors can be accommodated by the use of the internal mass flow sensor.