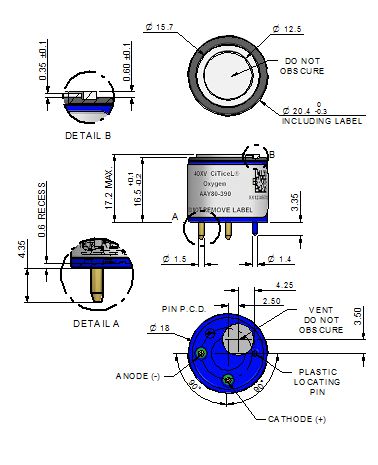

4OXVr Oxygen sensor

4OXV Oxygen O2 Electrochemical Gas Sensor - Replacement

* False alarm immunity

* Enhanced response time in extreme applications

* Reliably meets stated life

* Superior environmental performance

Measurement Range: 1 – 25% vol. O2. Maximum Overload: 30% vol. O2

What is Calibration Gas?

Calibration gas is a reference gas mixture used to calibrate and verify the accuracy of gas detectors, gas analyzers, and other gas monitoring equipment. These devices are commonly used in various industries, including industrial manufacturing, environmental monitoring, laboratories, and health and safety applications.

Calibration gases typically consist of a specific concentration of one or more target gases that the gas detector or analyzer is designed to detect. These gases can include toxic gases (such as hydrogen sulfide, carbon monoxide, or ammonia), combustible gases (such as methane or propane), or other gases of interest (such as oxygen or nitrogen dioxide).

The calibration process involves exposing the gas detector or analyzer to a known concentration of the calibration gas. If the device's readings match the expected concentration of the calibration gas, it is considered properly calibrated. Calibration is essential to ensure the accuracy and reliability of gas detection and analysis equipment, as the sensitivity of these devices can drift over time due to factors like sensor degradation, environmental conditions, and usage.

Calibration gases are usually supplied in pressurized cylinders and are traceable to national or international measurement standards. The concentrations of gases in these calibration mixtures are carefully certified to a high level of accuracy. Regular calibration helps maintain the precision of gas detection instruments and ensures that they provide trustworthy and accurate readings, which is crucial for ensuring workplace safety, environmental compliance, and quality control.

Please send us an e-mail to get more information about industrial chemical gas sensors and calibration gas instruments sales@spantech.co.uk

How to calibrate the gas sensor?

Calibrating a gas sensor involves adjusting the sensor's readings to match a known concentration of the target gas. The process may vary depending on the specific gas sensor and the manufacturer's instructions, but here is a general guide on how to calibrate a gas sensor:

Note: It's important to follow the manufacturer's guidelines and instructions for your specific gas sensor model, as calibration procedures can vary.

Materials Needed:

- Calibration gas cylinder with a known concentration of the target gas.

- Calibrating instrument or tubing (if required by the sensor).

- Screwdrivers or adjustment tools (if needed).

- Personal protective equipment (PPE) such as gloves and safety goggles.

Steps:

Choose a Suitable Location: Select a well-ventilated area where the calibration can be performed safely. Ensure that there is no exposure to harmful gases during the calibration process.

Prepare the Sensor: Turn on the gas sensor and allow it to warm up according to the manufacturer's instructions. Some sensors require a stabilization period before calibration.

Connect Calibration Gas: If your sensor requires it, connect the calibration gas cylinder to the sensor using a calibrating adapter or tubing. Make sure the connections are secure.

Initiate Calibration Mode: Many gas sensors have a specific calibration mode. Access this mode as per the manufacturer's instructions. This might involve pressing specific buttons or using software interfaces.

Enter Calibration Values: Depending on the sensor, you may be prompted to enter the concentration of the calibration gas or use predefined settings. Follow the instructions provided by the sensor's manual or display.

Wait for Stabilization: Allow the sensor to stabilize and adjust to the calibration gas concentration. This may take a few minutes.

Adjust Calibration: If the sensor's reading doesn't match the known concentration, some sensors allow you to adjust the calibration settings. This could involve using screwdrivers or adjustment tools to fine-tune the sensor's response.

Verify Calibration: Once the sensor readings stabilize and match the expected concentration, the calibration is successful. If adjustments were made, verify that the sensor's readings are accurate over a range of concentrations.

Document Calibration: Record the calibration details, including the calibration gas concentration, date, time, and any adjustments made. This documentation is important for quality control and compliance purposes.

Complete Calibration: Exit the calibration mode on the sensor and disconnect the calibration gas cylinder if necessary.

Routine Calibration: Gas sensors should be regularly calibrated as per the manufacturer's recommended schedule or when there are signs of drift or inaccuracy. Routine calibration ensures ongoing accuracy.

Always refer to the specific guidelines provided by the sensor manufacturer for the most accurate and up-to-date calibration instructions. Improper calibration can lead to inaccurate readings, compromising safety and measurement reliability. If you are unsure about the calibration process, it's advisable to seek assistance from qualified personnel or the manufacturer's technical support.

Please send us an e-mail to get more information about industrial chemical gas sensors and calibration gas instruments sales@spantech.co.uk